When implementing new technology that has the potential to make your manufacturing processes more efficient, it can be difficult to determine the right company to partner with. It’s important to partner with a company that not only has experience integrating these systems but also understands your business and its specific needs. There are many benefits of using Rockwell Automation integrators when implementing their products in your facility. An integrator can help you streamline communication between machines, reduce maintenance costs and streamline productivity by simplifying programming and maintenance processes. Depending on your needs and usage of machinery, there are several different types of Rockwell Automation integrators that can help you get the most out of your investment. Here is an overview of what you should look for in a Rockwell Automation integrator before choosing one as your partner.

What to Look for in a Rockwell Automation Integrator

In order to find the right integrator to work with, you should start by evaluating integrators based on these criteria.

Experience – The most important factor to consider when selecting an integrator is their experience working with Rockwell Automation products. This will allow them to fully understand your specific needs and help them find a solution that will work best for your business.

Service – After you’ve chosen an integrator based on their experience, you should also evaluate their customer service. This can help you get the most out of your investment by making the implementation process as seamless as possible.

References – One of the best ways to determine how an integrator operates is to reference previous customers. This will give you a better idea of how they will operate on your project and give you the confidence to move forward with this partnership.

Reviews – Another great way to determine how an integrator operates is to read reviews from past customers. This will give you an idea of how they interact with customers and how satisfied they are with the integrator’s services.

Managing the Initial Investment

One of the most important aspects of choosing an integrator is managing the initial investment. This includes both the upfront investment for the project and the ongoing maintenance costs associated with the system. Rockwell Automation integrators can help you find the right solution for your business. They can also help you determine the best initial investment needed for this project.

Identify the Problem – Before you start looking for a solution, you need to first identify the problem. By clearly identifying the problem and the source, you can better understand what you need in a solution. This will help you better evaluate potential integrators and find a solution that fits your needs.

Identify the Solution – Once you’ve identified the problem, you can then begin to evaluate potential solutions. This includes evaluating different integrators and their solutions.

Determine the Budget – Once you’ve determined the solution, you can then determine the budget for this investment. This will depend on your specific needs and the solutions that you’ve identified.

Streamline Communication Between Machines

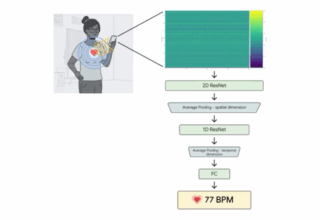

One of the biggest benefits that a Rockwell Automation integrator can provide is the ability to seamlessly communicate between machines. This is often referred to as distributed control system (DCS) functionality. This functionality is designed to allow you to fully integrate your processes and maximize the use of your machines by creating a smart factory. This functionality is especially important for manufacturers that produce goods that require multiple machines. By integrating these machines, you can improve communication and create a more streamlined process that makes it easier to identify and troubleshoot problems.

Reduce Maintenance Costs

A great way to reduce maintenance costs associated with your equipment is to integrate the systems that monitor these machines. This functionality is often referred to as computerized maintenance system (CMMS) functionality. CMMS functionality is designed to allow you to monitor your machines and create a database of maintenance schedules and issues. This will allow you to better track maintenance issues and find solutions to avoid potential problems that could delay production.